vibration monitoring: We are aware of the risks involved with physical access to local switch Box and vibration connection nodes. From dehydration, heat stroke, trip and fall hazard, dust and dirt and respiratory hazards, snake and spider bite hazard, noise, rotating equipment in vicinity, and many other hazards threating the condition monitoring and reliability technicians and maintenance personnel.

Industrial Vibration Monitoring Challenges:

- High Risk: Access to remote parts of the operation and unsafe access to working machinery in different weather conditions.

- Test Result Reliability: Human error in Manual testing and sampling procedures.

- Skilled Workforce Availability: there are occasions that technicians are not available when required.

- Costs and Expenses: Labour cost allocated for onsite staff when performing data collection.

Why Remote Vibration Monitoring Solution?

- Risk Elimination and Vibration Monitoring (dehydration, heatstroke, trip and fall hazard, dust and dirt and respiratory hazards, snake and spider bite hazard, noise, rotating equipment in vicinity, and many other hazards).

- Labor cost.

- Remote access to Vibration Monitoring data.

- An instant sampling at any time (Real-time data).

Specifications of Vibration Monitoring tool:

- 8/16 Channel Unit, Installed in the Switch Box Enclosure.

- Flexible Dashboard Design to Meet the Client’s Expectations.

- Utilization of Low Noise Channels to Power up the Sensors and Read their Data.

- Safe and Secure Data Transmission.

- Supports All AC Accelerometer Vibration Monitoring Sensors and 4-20mA Sensors.

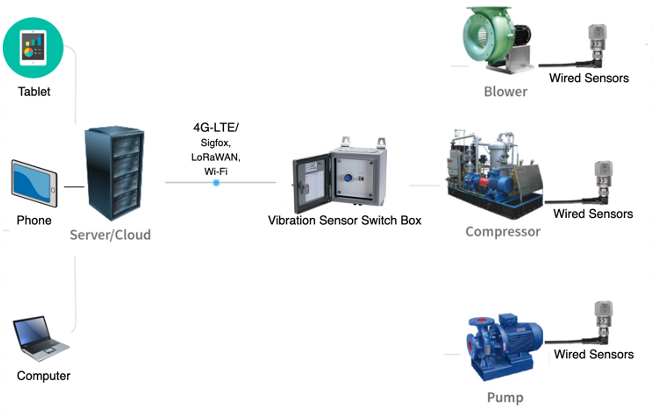

Solution Architecture:

Functions:

- Transfers the Data from the Vibration Sensors to a Server (Cloud or On-Premises).

- Independent from the Original Equipment Manufacturer (OEM) of the Vibration Sensors.

- The Units Required Internet Connectivity can be Achieved by Built-In 4G LTE Modem.

- Data Sent Through Mobile Network (or alternatively through Sigfox, LoRaWAN, Wi-Fi) to a Server.

- S5 System designed Hardware and Software. The Server can be a Cloud Server or an On-Premises Server, Owned by Us or by the Client (Optional).

- The Data can be Available Anytime Anywhere by Logging into the Dashboard via a Web Browser or Mobile Application.

Smart Wireless Vibration Monitoring:

Most of the machinery in plants run 24/7 under extreme environmental conditions. With Machine downtime costing thousands of dollars per hour, it is critical to have a solid predictive or preventative condition monitoring. Vibration monitoring is crucial in this process and contributes to a significant portion of condition monitoring.

Remote Wireless Vibration Monitoring Benefits:

- Remote real time Vibration Monitoring from any location.

- Avoid catastrophic failure by repairing or replacing components before failure (Equipment Predictive Maintenance).

- Reduce safety risk for onsite technicians and engineers.

- Prevent unscheduled machine downtime.

Wireless Vibration Monitoring and Temperature Sensor:

- Simultaneous measurement of (Acceleration, Velocity, Displacement and Temperature).

- Spectrum/waveform representation of vibration Signal.

- Self-inspect function (Real time warning for abnormal).

- IP67, dustproof & waterproof.

- Utilizes Zigbee Communication.

- Designed for onsite use.

- Strong anti-jamming capability (Prevents being jammed from communication interferences).

- Easy Installation and maintenance.

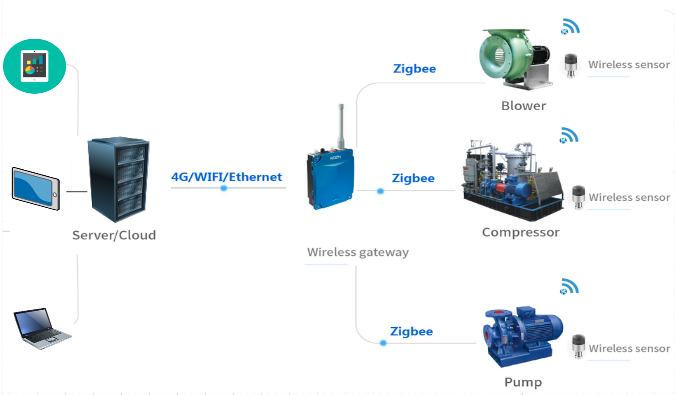

Solution Architecture:

Wireless Gateway of Vibration Monitoring:

- Capable of sending data to server using 4G/WI-FI/Ethernet.

- High resolution data collection (Vibration & Temperature).

- Synchronous data Acquisition across all channels.

After reading Vibration Monitoring you can also read about solutions-applications